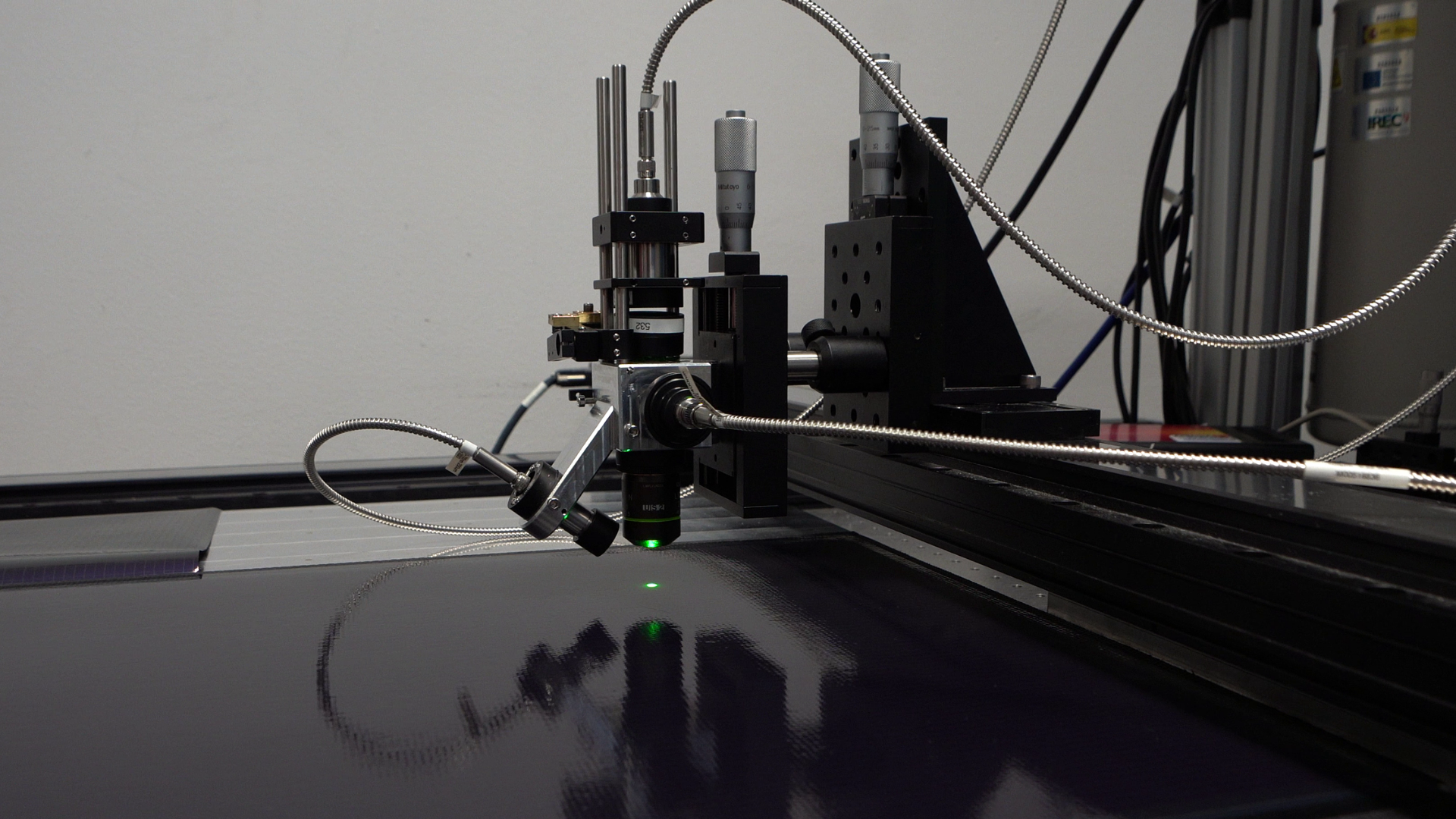

IREC has developed an innovative method of quality control and industrial monitoring compatible with industry 4.0 that allows optimizing the production of complex materials in different fields, such as the manufacturing of smart photovoltaic windows, or the recycling of laminated glass. This allows lowering large-scale production costs by increasing the performance of industrial processes, reducing the environmental impact and facilitating the energy transition for a more sustainable society.

The production of complex devices involves multiple layers of various materials and different manufacturing steps with a large number of control parameters. The analysis of these devices on an industrial scale is usually performed once the product is finished. However, it is key to detect defects in each of these layers as soon as possible, in order to take corrective measures and prevent the production of defective devices.

The European project consortium Solar-Win has put these concepts of quality control and industrial monitoring into practice to develop smart photovoltaic windows. The Solar Energy Materials and Systems group at IREC contributes its ‘know-how’ to support the participating companies – the Dutch Physee and the Austrian Sunplugged – in optimizing their manufacturing processes to obtain more efficient photovoltaic devices and coatings for window glass.

This methodology will also be applied to the quality control of laminated glass recycling processes, within the framework of the new European SUNRISE project recently started.

Read the related press release: